composite testing

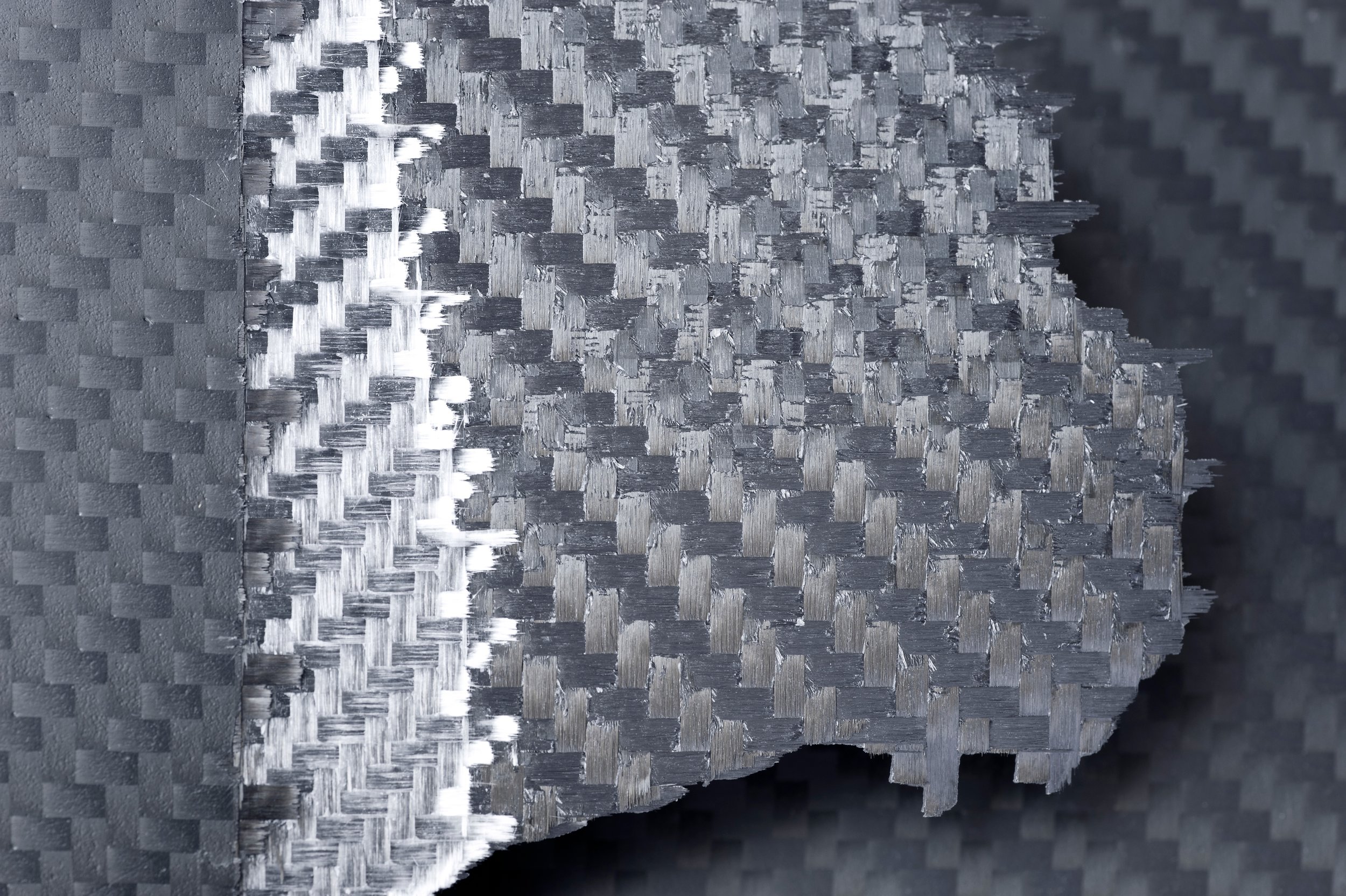

MES offers mechanical, chemical and surface analysis of composite materials.

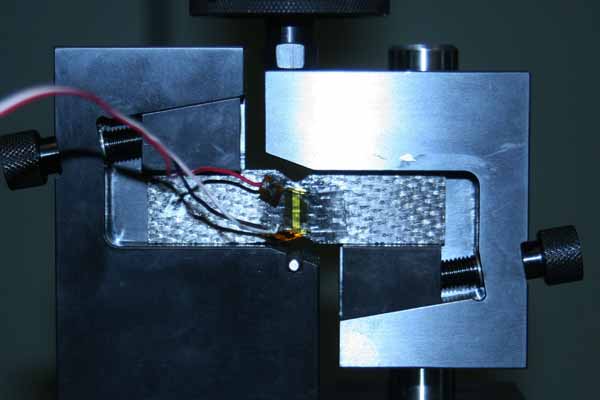

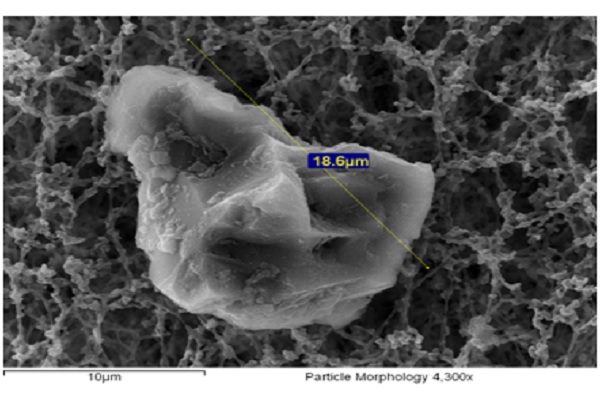

Our composite test lab experts understand the challenges of testing composites due to their complex mechanical behavior and inhomogeneous build. To ensure mechanical integrity of your materials, we utilize innovative solutions and precision fixtures to provide accurate results in a timely manner.

Our extensive experience in composite testing allows us to offer a one stop shop for mechanical testing and micro analysis. We offer testing at a range of test temperatures and provide volume discounts for large orders. MES offers testing on thermosets, thermoplastics, laminates, fiber reinforced composites, core materials, resins, films and adhesives.

COMPOSITES

Tensile properties (tensile, modulus and elongation)

Flexural strength

Adhesive strength

Compressibility

Percent volatiles

Cross-sectional multiple layer-film thickness

Molecular weight distribution

Additive and resin identification

Chemical family, including base polymer characterization

APPLICATIONS

Witness panel testing

R&D of new materials

Reverse engineering

SAMPLE REQUIREMENTS

Sample Diameter Sizes – 1″ to 40+” diameter

Removal of about 1 meter of insulation

Surface preparation to scrape off loose paint or scale

CAPABILITIES

Temperatures -100 to 1,000°F

On-site conditioning

SPECIFICATIONS

ASTM C297 - Flatwise Tensile Strength

ASTM C364 - Edgewise Compressive Strength

ASTM D695 - Compression Rigid Plastics

ASTM D790 - Three-Point Flexure

ASTM D2344 - Short-Beam Strength

ASTM D3039/D3039M - Tensile Properties

ASTM D3410 - Compressive Properties

ASTM D3846 - In-Plane Shear Strength

ASTM D4255 - In-Plane Shear Properties

(Rail Shear Method)

ASTM D5766 - Open-Hole Tensile Strength

ASTM D6272 - Flexural Properties

ASTM D6484 - Open-Hole Compressive Strength

ASTM D6641 - Compressive Properties

ASTM D7078 - Shear Properties

(V-Notched Rail Shear Method)

ASTM D7249 - Flexural Properties

ASTM D7264 - Flexural Properties